FAQ – Turbines and Pumps

Do you actually remove material when polishing metal?

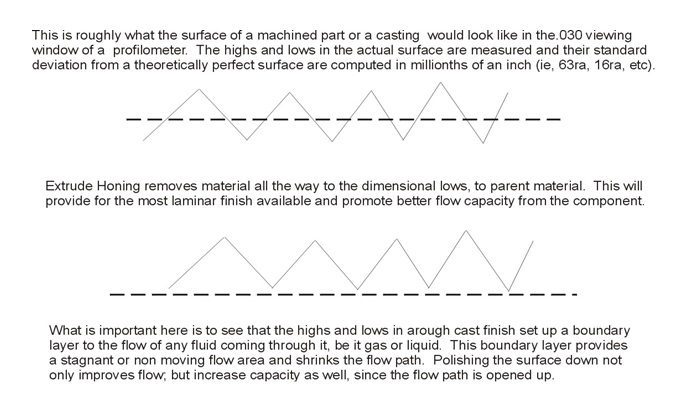

Yes, we do. How much material removal depends on the roughness of the surface at start.

In most cases, an average machined finish (approximately 125ra) would require removal of approximately .0015-.004 inches of material to bring it to a 63ra. In the case of a cast finish, the surface being rougher (ie 250ra), there would be more removed.

How do you control the amount of material removed?

Primary variables are the tooling, the media flow pressure, the viscosity and abrasive concentration of the media.

The tooling is a holding fixture that directs media flow to the target area of the part, while protecting areas where abrasion is not desired. Media flow pressure available has a range of 200 to 2000 psi.

The media carrier, silicon rubber, comes in three basic viscosities: high, medium and low; while the silicon carbide abrasive ranges in size from the fineness of baby powder to the coarseness of buckshot.

All these taken together are manipulated to produce the desired result on the workpiece. For this reason, each and every application destined for Extrude Hone AFM has to be engineered and developed.