Our abrasive flow machining process is totally customizable to your needs.

The rate at which material is removed from the surface by the abrasive media depends on several factors:

- Type of material

- Hardness of material

- Quality or density of material

- Size and amount of passages to be processed

Media:

- Media flow rate or speed of each pass or cycle

- Media carrier viscosity: high, medium, low, or different combinations of 2 will change the characteristics of the media's effectiveness on different materials and hole sizes

- Abrasive particle size: ranging from a fine powder-like 1000-grit to 8-grit comparable to small rocks or gravel

- Abrasive concentration per pound of media

You Control the Process

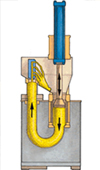

AFM is a controllable machining process. You can control the media flow rate and pressure, volume, and type of media, media temperature, and, consequently, the amount of material that is removed. For any given application, the surface finish improvement, radius generation and/or stock removal can be determined and monitored to ensure repeatability.

Get a Customized Solution for Your Application

If you would like to learn more about how our AFM Process technology can help you achieve your desired specs for your specific application, please contact us at (562) 531-2976 today.