Extrude Hone AFM offers expert abrasive flow machining in Indianapolis IN for all your metal parts finishing needs

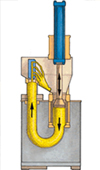

Whether you are producing metal parts yourself by casting, laser sintering, EDM, or conventional machining, or working with aftermarket parts, chances are you are going to need some surface improvements to remove imperfections. For simple applications, such as large holes or simple passages, manual polishing or electrochemical deburring might be sufficient. But, if your needs are more complex, you may be looking for a different solution that can meet your strict specifications.

Fortunately, Extrude Hone AFM offers a service equal to the most complex needs:

Abrasive Flow Machining in Indianapolis IN.

- It can be used on any metal, from hardened, difficult-to-machine super alloys to soft metals like aluminum

- It reaches areas hand tools and line-of-sight methods cannot

- Both roughing and finishing can be completed in one process

- Tooling can be created to selectively direct flow to the areas or passages requiring improvement

- The process can be tailored to provide aggressive removal or delicate honing to your exact specs

Uses for Abrasive Flow Machining in Indianapolis IN

- Radiussing: Edges of discs and blades can be finished to a high standard to enhance strength and performance.

- Surface Stress Relief: EDM recast layers can be removed to eliminate risk of failure on highly stressed components.

- Polishing: No matter how complex the shape of a part or passage, abrasive flow machining in Indianapolis IN can be used to deliver a uniform surface improvement.

- Geometry Optimization: AFM can be used as an aftermarket improvement on engine parts like manifolds, turbines, pumps, and hydraulic parts to optimize flow through the passages without affecting volume. AFM is also very useful for resizing precision dies.

- Deburring: Burrs of any size can alter flow or otherwise detract from highly precise processes. They are especially problematic for food and medical applications because they can harbor bacteria. AFM provides a simple way to remove burrs and other imperfections, improving surface finishes by 90 percent with minimal dimensional change.

Partner with Extrude Hone AFM Today

As an expert in abrasive flow machining in Indianapolis IN, Extrude Hone AFM makes an excellent choice of partner for enhancing your metal parts. Call (562) 531-2976 or use our online contact form for a quote or more information.