Our abrasive flow deburring in Kansas City MO can finish metal parts to the most exacting standards

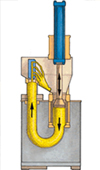

No matter what type of manufacturing process is used to fabricate a metal part, the results will not be perfect. Instead, tiny, jagged burrs will be left behind somewhere on the part. When it comes to removing these imperfections, the traditional methods of manual deburring and electrochemical deburring often leave a lot to be desired--especially if you need a highly precise result. The good news is, you’ve found a better alternative at Extrude Hone AFM. We can provide abrasive flow deburring in Kansas City MO to:

- Remove burrs from any internal or external edge, slot, hole, or passage with a non-reactive media

- polish cross-drilled and intersecting holes with ease

- Work on any type of metal such as titanium, Iconel, aluminum, copper, bronze, etc.

- Perform roughing and finishing in one pass

- Deliver highly precise and repeatable results

How does abrasive flow deburring achieve all this?

- Type of metal

- Media viscosity

- Abrasive particle size and concentration

- Media flow rate, pressure, and temperature

Now you might wonder…

What are some ideal applications for abrasive flow deburring in Kansas City MO?

- Aerospace: Abrasive flow deburring in Kansas City MO can enhance aerospace applications in many ways, from improving airfoil surface conditions to creating true radius edges to reducing mechanical fatigue around holes and attachments.

- Automotive Engines: Extrude Hone AFM discovered the benefits of abrasive flow deburring in Kansas City MO to improve the efficiency and performance of combustion engines, and today our process is routinely used by major manufacturers like Ford and Cadillac. The most commonly deburred automotive part is the intake manifold. By smoothing all the internal passages in the manifold, our process can improve the efficiency of combustion and reduce emissions.

- Food Processing Equipment: Burrs can contaminate food products with metal if they snap off during processing. They can also trap food particles long enough for them to spoil, introducing bacteria into the product. Because our Ultra Pure process is so effective at removing burrs, it is a real boon for the food processing industry.

Call Now to Learn More

If you have questions about abrasive flow deburring or about Extrude Hone AFM, contact us by calling (562) 531-2976 or submitting an online contact form. Don’t forget--we can handle project of all sizes, from aftermarket improvements on one single auto part to professional deburring for thousands of newly manufactured parts.