Our abrasive flow deburring in Orange CA can finish metal parts to the most exacting standards

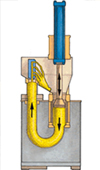

Metal products created by EDM, laser sintering, casting, or conventional machining will require some type of finishing to remove burrs and other imperfections left by the manufacturing process. While there are a variety of different deburring technologies available for this purpose, only abrasive flow deburring in Orange CA can:

- Reach any internal or external surface with a chemically inactive media

- Handle complex arrays of cross-drilled and intersecting holes with ease

- Be applied to any metal from the hardest super alloys to soft aluminum or copper

- Perform roughing and finishing in one pass

- Deliver highly precise and repeatable results

How does it achieve all this?

- Type of metal

- Media viscosity

- Abrasive particle size and concentration

- Media flow rate, pressure, and temperature

Now you might wonder…

What are some ideal applications for abrasive flow deburring in Orange CA?

- Aerospace: The abrasive flow deburring process was actually invented for the aerospace industry. At Extrude Hone AFM, we continue to provide abrasive flow deburring in Orange CA up to the extremely high standards and tight tolerances required for aerospace applications.

- Automotive Engines: Extrude Hone AFM discovered the benefits of abrasive flow deburring in Orange CA to improve the efficiency and performance of combustion engines, and today our process is routinely used by major manufacturers like Ford and Cadillac. The most commonly deburred automotive part is the intake manifold. By smoothing all the internal passages in the manifold, our process can improve the efficiency of combustion and reduce emissions.

- Food Processing Equipment: Burrs can contaminate food products with metal if they snap off during processing. They can also trap food particles long enough for them to spoil, introducing bacteria into the product. Because our Ultra Pure process is so effective at removing burrs, it is a real boon for the food processing industry.

Call Now to Learn More

Whether you need a way to put the finishing touches on parts made by your company, or you want to make some aftermarket improvements to your engine parts, Extrude Hone AFM is here to help. Call us at (562) 531-2976 to learn more.