Extrude Hone AFM offers expert abrasive flow deburring in San Jose CA for all your metal parts finishing needs

Depending on the type of metal part in question and the type of finishing needed, you may have a variety of options. But the more complex your needs and the more exacting your specs, the smaller your field of options for finishing becomes.

The good news is, you’ve found a process that can help at Extrude Hone AFM:

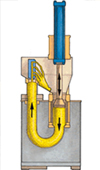

Abrasive Flow Deburring in San Jose CA.

- With the right abrasive grit and viscosity of polymer media, AFM can be used on any metal from titanium to aluminum

- It reaches areas hand tools and line-of-sight methods cannot

- Both roughing and finishing can be completed in one process

- The entire workpiece need not be finished--we can direct flow selectively using the tooling

- We can control different variables in the process to meet your exact specs

Uses for Abrasive Flow Deburring in San Jose CA

- Radiussing: AFM can be used to generate continuous, true-edge radii ideal for jet engine discs and other aerospace applications.

- Surface Stress Relief: EDM recast layers can be removed to eliminate risk of failure on highly stressed components.

- Polishing: Even the most complex shapes of metal parts and the most convoluted of internal passages can be smoothed evenly with abrasive flow deburring in San Jose CA. Our process is sensitive enough for even the most delicate honing, enhancing the finish without exceeding the blueprint specs.

- Geometry Optimization: By using AFM to smooth and shape passages, air, gas, or liquid behavior can be improved for reduced cavitation and enhanced performance in engines, turbines, pumps, and hydraulic parts. AFM can also accurately adjust the size of precision dies while also enhancing their service life.

- Deburring: Even the tiniest metal burrs can interfere with the performance of a part, or even put human health at risk in the case of burr trapping bacteria in a food processing or medical component. With AFM, burrs can be removed without risk of damage or contamination to the passages in the part. The polymer media will carry them totally away.

Partner with Extrude Hone AFM Today

As an expert in abrasive flow deburring in San Jose CA, Extrude Hone AFM makes an excellent choice of partner for enhancing your metal parts. Call (562) 531-2976 or use our online contact form for a quote or more information.