Extrude Hone AFM offers expert abrasive flow machining in Santa Ana CA for all your metal parts finishing needs

Depending on the type of metal part in question and the type of finishing needed, you may have a variety of options. Unfortunately, traditional methods may not be equal to your needs on a more complex job. For example, manual polishing is extremely tedious and costly work, and isn’t effective on extremely convoluted passages.

The good news is, Extrude Hone AFM offers a service equal to the most complex needs:

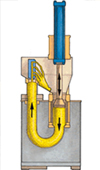

Abrasive Flow Machining in Santa Ana CA.

- The process can be used on any metal including titanium, Iconel, copper, aluminum, bronze, and other alloys

- It reaches areas hand tools and line-of-sight methods cannot

- Both roughing and finishing can be completed in one process

- You can finish multiple passages at once or direct flow to one passage at a time using the appropriate tooling

- The process can be controlled with incredible precision to meet your exact specs

Uses for Abrasive Flow Machining in Santa Ana CA

- Radiussing: Edges of discs and blades can be finished to a high standard to enhance strength and performance.

- Surface Stress Relief: By polishing away EDM recast layers, potential sources of surface stress can be removed to reduce the likelihood of metal fatigue leading to parts or system failure.

- Polishing: No matter how complex the shape of a part or passage, abrasive flow machining in Santa Ana CA can be used to deliver a uniform surface improvement.

- Geometry Optimization: AFM can be used as an aftermarket improvement on engine parts like manifolds, turbines, pumps, and hydraulic parts to optimize flow through the passages without affecting volume. AFM can also accurately adjust the size of precision dies while also enhancing their service life.

- Deburring: Even the tiniest metal burrs can interfere with the performance of a part, or even put human health at risk in the case of burr trapping bacteria in a food processing or medical component. With AFM, burrs can be removed without risk of damage or contamination to the passages in the part. The polymer media will carry them totally away.

Partner with Extrude Hone AFM Today

Extrude Hone AFM is a 40-year industry veteran. We know abrasive flow machining in Santa Ana CA and we are confident we can deliver the high quality improvements you need. Call us at (562) 531-2976 or contact us online to get a quote or to learn more about partnering with us.