Do you own or work for a company based out of Anaheim, California? Perhaps in the automotive, hydraulics, food processing, or another industry that utilized machined components? If so, then you should seriously consider sending your essential machined parts to Extrude Hone AFM. We have a patented process that will surface finish and polish every inch of your components so each of your machines will perform better than ever.

Complete customization for businesses in Anaheim

Call Extrude Hone AFM at (562) 531-2976 or use our online contact form to request your free custom estimate today. Each estimate is calculated separately because each application of our patented process is different. Extrude Hone AFM customizes each application in various ways to achieve precise intended results.

How it works for your Anaheim-based company

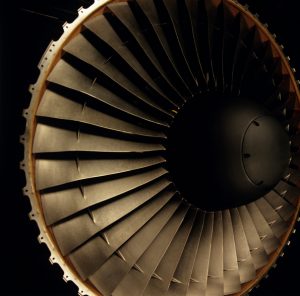

During the AFM process, a hydraulic ram pushes abrasive media through the metal component, performing erosion on every nook and cranny. Abrasive particles in the media remove even microscopic features on the surface of the workpiece and effectively remove them. During this process, the media becomes a flexible file (also called a slug) that conforms perfectly to the shape of your workpiece. Wherever the media flow is restricted, the most material is removed from the component because the flow speed and pressure of the media increase there. As a result of the pressure the media puts on all surfaces, the component has a very uniform finish at the end of the AFM process.

Material removal rate

One of the most frequently asked questions we always receive is, can you control exactly how much material is removed during the AFM process? Our answer is always, “yes, of course!” The rate at which material is removed from the surface of the metal component by the abrasive media depends on various essential factors related to the workpiece and the media.

Workpiece:

- Type of material

- Hardness of material

- Quality or density of material

- Size and amount of passages to be processed

Media:

- Media flow rate or speed of each pass or cycle

- Media carrier viscosity: high, medium, low, or different combinations of 2 will change the characteristics of the media’s effectiveness on different materials and hole sizes

- Abrasive particle size: ranging from a fine powder-like 1000-grit to 8-grit comparable to small rocks or gravel

- Abrasive concentration per pound of media

Custom internal polishing in Anaheim, CA

As previously mentioned, the AFM process is customized for each specific application. It’s a totally controllable machining process. For each application, we control the media flow rate and pressure, volume, and type of media, media temperature, and thus the amount of material that is removed during the AFM process. Consequently, the surface finish improvement, radius generation, and/or stock removal can be precisely predicted, achieved, and monitored to ensure repeatability on all machined parts.

Get your free custom estimate now

We invite you to contact us today to request a free custom estimate. You can call us at (562) 531-2976 or use this online contact form.