Our abrasive flow deburring in Fort Worth TX can finish metal parts to the most exacting standards

When it comes to manufacturing metal parts, even the most precise methods can leave behind burrs or other imperfections that could impair the integrity of the part itself or the larger system in which it will be used. Obviously this needs to be fixed before you install the part. Manual deburring can only reach so far into a part and is hard to perform evenly. Electrochemical deburring can reach further, but is not suitable for all metals. Abrasive flow deburring in Fort Worth TX provides an incredibly beneficial alternative. It can:

- Deburr any internal or external edge, slot, hole, or passage with a non-reactive media

- polish cross-drilled and intersecting holes with ease

- Work on any type of metal such as titanium, Iconel, aluminum, copper, bronze, etc.

- Perform roughing and finishing in one pass

- Remove material uniformly without altering the geometry of the part

How does it achieve all this?

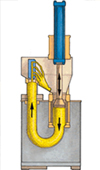

Abrasive flow deburring in Fort Worth TX is a specific type of abrasive flow machining process that utilizes an abrasive-laden polymer media that can selectively and controllably abrade the surfaces it flows across. Our polymers are designed to keep the abrasive particles suspended uniformly at all times, while also allowing them to recirculate so fresh abrasive is always available where the polymer meets the surface being deburred. The process is highly customizable, enabling us to remove imperfections large and small from all kinds of metals. Our technicians know exactly how to adjust the following factors to give the exact results you want:

- Media viscosity

- Abrasive particle size and concentration

- Media flow rate, pressure, and temperature

Now you might wonder…

What are some ideal applications for abrasive flow deburring in Fort Worth TX?

Because it can be controlled so precisely, abrasive flow deburring in Fort Worth TX is ideal for any application where internal passages, slots, or holes need to be smoothed. However, at Extrude Hone AFM we have special expertise in abrasive flow deburring for:

- Aerospace: Abrasive flow deburring in Fort Worth TX can enhance aerospace applications in many ways, from improving airfoil surface conditions to creating true radius edges to reducing mechanical fatigue around holes and attachments.

- Automotive Engines: Extrude Hone AFM pioneered the process of abrasive flow deburring for automotive engines. By uniformly smoothing and polishing the interior passages of parts like intake manifolds, abrasive flow deburring in Fort Worth TX can increase air and fuel flow through the engine, thus increasing horsepower, thrust, torque, and efficiency.

- Food Processing Equipment: It is extremely important for food processing equipment to be totally smooth. Why? Because rough surfaces can trap bacteria and lead to contamination. Hundreds of companies have benefited from Extrude Hone’s Ultra Pure deburring process, which can remove both burrs and cavities to ensure quality results from all kinds of food processing equipment.

Call Now to Learn More

Extrude Hone AFM can assist with deburring projects of all sizes, whether you have one part for your muscle car or a thousand parts for your business.Call us at (562) 531-2976 to learn more.