Our abrasive flow deburring in Atlanta GA can finish metal parts to the most exacting standards

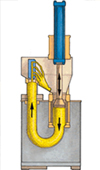

A 100 percent perfect manufacturing process has not been invented yet. Even the most high-tech methods can leave behind microscopic burrs and other imperfections. When it comes to removing these imperfections, the traditional methods of manual deburring and electrochemical deburring often leave a lot to be desired--especially if you need a highly precise result. The good news is, you’ve found a better alternative at Extrude Hone AFM. We can provide abrasive flow deburring in Atlanta GA to:

- Reach any internal or external edge, slot, hole, or passage with a non-reactive media

- Handle cross-drilled and intersecting holes with ease

- Work on any type of metal such as titanium, Iconel, aluminum, copper, bronze, etc.

- Provide roughing and finishing in one pass

- Remove material uniformly without altering the geometry of the part

How does abrasive flow deburring achieve all this?

- Type of metal

- Media viscosity

- Abrasive particle size and concentration

- Media flow rate, pressure, and temperature

Now you might wonder…

What are some ideal applications for abrasive flow deburring in Atlanta GA?

- Aerospace: When it comes to aerospace applications, precision is of the utmost importance. It makes sense to continue to use abrasive flow deburring in Atlanta GA to finish all kinds of aerospace parts, as this highly precise method was actually invented for aerospace in the first place.

- Automotive Engines: Whether it is air or fuel flowing through the passages in an engine part, any turbulence is going to decrease efficiency. Using abrasive flow deburring in Atlanta GA, we can reduce turbulence and increase flow up to 25 percent. This in turn encourages more complete combustion for better fuel efficiency, power, and performance.

- Food Processing Equipment: Burrs can contaminate food products with metal if they snap off during processing. They can also trap food particles long enough for them to spoil, introducing bacteria into the product. Treating parts with our Ultra Pure abrasive flow machining process can prevent these issues.

Call Now to Learn More

If you would like to learn more about our services, please Call us at (562) 531-2976 or fill out our online contact form. Remember, we can deliver the same high-quality results whether you have one part of a thousand to deburr.