Extrude Hone AFM offers expert abrasive flow machining in Atlanta GA for all your metal parts finishing needs

Do you need to remove burrs from the holes or passages in a metal part? If your needs are simple, manual polishing or electrochemical deburring might work. But, if your needs are more complex, you may be looking for a different solution that can meet your strict specifications.

Fortunately, you’ve found a process that can help at Extrude Hone AFM:

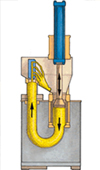

Abrasive Flow Machining in Atlanta GA.

- With the right abrasive grit and viscosity of polymer media, AFM can be used on any metal from titanium to aluminum

- Hidden slots, convoluted passages, and cross drilled holes can all be finished with ease

- It provides roughing and finishing in one pass

- You can finish multiple passages at once or direct flow to one passage at a time using the appropriate tooling

- The process can be tailored to provide aggressive removal or delicate honing to your exact specs

Uses for Abrasive Flow Machining in Atlanta GA

- Radiussing: AFM can be used to generate continuous, true-edge radii ideal for jet engine discs and other aerospace applications.

- Surface Stress Relief: Without proper finishing, EDM recast layers and other types of fatigue or stress points can lead to crack propagation and premature parts failure.

- Polishing: With abrasive flow machining in Atlanta GA, every millimeter of the workpiece can be polished evenly to deliver the desired surface improvement.

- Geometry Optimization: By using AFM to smooth and shape passages, air, gas, or liquid behavior can be improved for reduced cavitation and enhanced performance in engines, turbines, pumps, and hydraulic parts. AFM is also very useful for resizing precision dies.

- Deburring: Burrs of any size can alter flow or otherwise detract from highly precise processes. They are especially problematic for food and medical applications because they can harbor bacteria. With AFM, burrs can be removed without risk of damage or contamination to the passages in the part. The polymer media will carry them totally away.

Partner with Extrude Hone AFM Today

Extrude Hone AFM is a 40-year industry veteran. We know abrasive flow machining in Atlanta GA and we are confident we can deliver the high quality improvements you need. Call us at (562) 531-2976 or contact us online to get a quote or to learn more about partnering with us.