Extrude Hone AFM offers expert abrasive flow machining in Charlotte NC for all your metal parts finishing needs

Do you need to remove burrs from the holes or passages in a metal part? If your needs are simple, manual polishing or electrochemical deburring might work. But the more complicated the shape of your part, and the more exacting the specifications for the interior geometry of the part, the less satisfactory these methods become.

The good news is, you’ve found a process that can help at Extrude Hone AFM:

Abrasive Flow Machining in Charlotte NC.

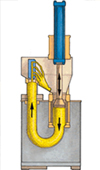

In abrasive flow machining in Charlotte NC, a hydraulic ram is used to push an abrasive-laden polymer media through the workpiece. This results in controlled erosion of the surfaces that the media comes in contact with. Compared to other finishing methods, abrasive flow machining offers several important benefits:

In abrasive flow machining in Charlotte NC, a hydraulic ram is used to push an abrasive-laden polymer media through the workpiece. This results in controlled erosion of the surfaces that the media comes in contact with. Compared to other finishing methods, abrasive flow machining offers several important benefits:

- With the right abrasive grit and viscosity of polymer media, AFM can be used on any metal from titanium to aluminum

- Hidden slots, convoluted passages, and cross drilled holes can all be finished with ease

- Both roughing and finishing can be completed in one process

- Tooling can be created to selectively direct flow to the areas or passages requiring improvement

- The process can be controlled with incredible precision to meet your exact specs

Uses for Abrasive Flow Machining in Charlotte NC

- Radiussing: Edges of discs and blades can be finished to a high standard to enhance strength and performance.

- Surface Stress Relief: EDM recast layers can be removed to eliminate risk of failure on highly stressed components.

- Polishing: With abrasive flow machining in Charlotte NC, every millimeter of the workpiece can be polished evenly to deliver the desired surface improvement.

- Geometry Optimization: By using AFM to smooth and shape passages, air, gas, or liquid behavior can be improved for reduced cavitation and enhanced performance in engines, turbines, pumps, and hydraulic parts. AFM can also accurately adjust the size of precision dies while also enhancing their service life.

- Deburring: Even the tiniest metal burrs can interfere with the performance of a part, or even put human health at risk in the case of burr trapping bacteria in a food processing or medical component. AFM provides a simple way to remove burrs and other imperfections, improving surface finishes by 90 percent with minimal dimensional change.

Partner with Extrude Hone AFM Today

As an expert in abrasive flow machining in Charlotte NC, Extrude Hone AFM makes an excellent choice of partner for enhancing your metal parts. Call (562) 531-2976 or use our online contact form for a quote or more information.