Our abrasive flow deburring in San Francisco CA can finish metal parts to the most exacting standards

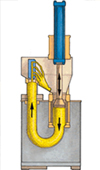

Whether you’re using conventional manufacturing techniques or the latest 3D laser sintering methods to produce a metal part or prototype, you’re going to end up with burrs. These burrs must be removed to get the best performance from your part. Manual deburring can only reach so far into a part and is hard to perform evenly. Electrochemical deburring can reach further, but is not suitable for all metals. Abrasive flow deburring in San Francisco CA provides an incredibly beneficial alternative. It can:

- Remove burrs from any internal or external surface with a non-reactive media

- Handle complex arrays of cross-drilled and intersecting holes with ease

- Work on any type of metal such as titanium, Iconel, aluminum, copper, bronze, etc.

- Provide roughing and finishing in the same pass

- Deliver highly precise and repeatable results

How does it achieve all this?

- Media viscosity

- Abrasive particle size and concentration

- Media flow rate, pressure, and temperature

Now you might wonder…

What are some ideal applications for abrasive flow deburring in San Francisco CA?

Well, due to the highly customizable nature of the process, which can be controlled to aggressively remove material or deliver the finest surface honing, the potential applications of abrasive flow deburring in San Francisco CA are virtually infinite. But there are some industries where it is used more often. For example, Extrude Hone AFM frequently does work for:

- Aerospace: The abrasive flow deburring process was actually invented for the aerospace industry. At Extrude Hone AFM, we continue to provide abrasive flow deburring in San Francisco CA up to the extremely high standards and tight tolerances required for aerospace

- Automotive Engines: Whether it is air or fuel flowing through the passages in an engine part, any turbulence is going to decrease efficiency. Using abrasive flow deburring in San Francisco CA, we can reduce turbulence and increase flow up to 25 percent. This in turn encourages more complete combustion for better fuel efficiency, power, and performance.

- Food Processing Equipment: All the surfaces that food comes into contact with during processing need to be clean and smooth. If you have burrs, you could easily end up with contamination from bacteria or even from tiny bits of metal if the burrs break off during processing. At Extrude Hone, we’ve developed a deburring process called Ultra Pure that is specifically designed to meet the needs of the food processing industry.

Call Now to Learn More

Extrude Hone AFM can assist with deburring projects of all sizes, whether you have one part for your muscle car or a thousand parts for your business.Call us at (562) 531-2976 to learn more.