Extrude Hone AFM offers expert abrasive flow machining in Torrance CA for all your metal parts finishing needs

Depending on the type of metal part in question and the type of finishing needed, you may have a variety of options. But the more complex the part--and the higher the level at which it will be expected to perform--the more difficult proper finishing becomes.

The good news is, at Extrude Hone AFM we have the solution you need:

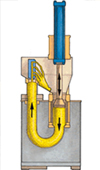

Abrasive Flow Machining in Torrance CA.

- With the right abrasive grit and viscosity of polymer media, AFM can be used on any metal from titanium to aluminum

- AFM can reach even the most hidden holes, slots, and passages that would be inaccessible to other methods

- It provides roughing and finishing in one pass

- The entire workpiece need not be finished--we can direct flow selectively using the tooling

- The process can be tailored to provide aggressive removal or delicate honing to your exact specs

Uses for Abrasive Flow Machining in Torrance CA

- Radiussing: By providing a gentle, even, and continuous radiused edge AFM can enhance all kinds of parts, including aerospace parts like jet engine discs.

- Surface Stress Relief: By polishing away EDM recast layers, potential sources of surface stress can be removed to reduce the likelihood of metal fatigue leading to parts or system failure.

- Polishing: No matter how complex the shape of a part or passage, abrasive flow machining in Torrance CA can be used to deliver a uniform surface improvement.

- Geometry Optimization: By using AFM to smooth and shape passages, air, gas, or liquid behavior can be improved for reduced cavitation and enhanced performance in engines, turbines, pumps, and hydraulic parts. AFM can also accurately adjust the size of precision dies while also enhancing their service life.

- Deburring: Even the tiniest metal burrs can interfere with the performance of a part, or even put human health at risk in the case of burr trapping bacteria in a food processing or medical component. With AFM, burrs can be removed without risk of damage or contamination to the passages in the part. The polymer media will carry them totally away.

Partner with Extrude Hone AFM Today

If you have any metal parts that could benefit from abrasive flow machining in Torrance CA, please contact us today to learn more about our process and get a quote on your job.